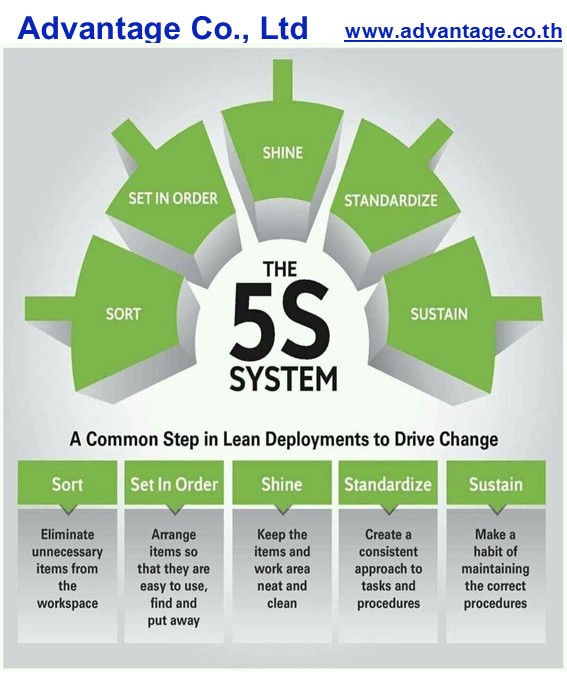

การ 5S System is a structured methodology designed to create and maintain an organized, efficient, and safe workplace. Originating from Japan, the five pillars—Sort, Set in Order, Shine, Standardize, and Sustain—form the basis for continuous improvement and operational discipline in any organization.

1. Sort (Seiri) – Eliminate the Unnecessary

Purpose:

To identify and remove items that are not required for daily operations, minimizing clutter and improving efficiency.

Key Activities:

- Inspect all tools, materials, and equipment in the work area.

- Remove or dispose of items that are outdated, broken, or unnecessary.

- Clearly define criteria for what is needed and what is not.

- Create a “red-tag” area for items awaiting evaluation or disposal.

Outcome:

A cleaner, more focused workspace with only essential items available for use.

2. Set in Order (Seiton) – Organize for Efficiency

Purpose:

To arrange necessary items so they are easy to access, use, and return—enhancing workflow and minimizing wasted motion.

Key Activities:

- Assign specific locations for each tool, material, and document.

- Use visual management tools such as labels, shadow boards, and floor markings.

- Arrange items based on frequency of use and ergonomic principles.

Outcome:

A well-organized workspace where everything has a designated place and can be located instantly.

3. Shine (Seiso) – Clean and Inspect

Purpose:

To maintain a clean and safe working environment while fostering a sense of ownership and pride among employees.

Key Activities:

- Conduct regular cleaning, inspection, and maintenance routines.

- Identify sources of dirt, leaks, or damage and correct them at the root cause.

- Involve all team members in daily cleaning activities as part of their responsibilities.

Outcome:

A workplace that is visually clean, safe, and conducive to high-quality performance.

4. Standardize (Seiketsu) – Establish Best Practices

Purpose:

To create consistent standards and procedures that sustain the improvements achieved through the first three steps.

Key Activities:

- Develop Standard Operating Procedures (SOPs), checklists, and visual guides.

- Define schedules for cleaning, organizing, and auditing activities.

- Ensure that responsibilities are clearly assigned and documented.

Outcome:

Uniform practices across the organization, ensuring consistency and accountability.

5. Sustain (Shitsuke) – Maintain and Improve

Purpose:

To embed the 5S principles into the organizational culture, promoting discipline, responsibility, and continuous improvement.

Key Activities:

- Provide ongoing training and awareness programs for all employees.

- Conduct regular audits, reviews, and feedback sessions.

- Recognize and reward teams that demonstrate strong 5S performance.

- Encourage continuous improvement through employee involvement and innovation.

Outcome:

A sustainable culture of excellence where 5S becomes a daily habit, not a one-time project.